SURFBOARDS

Hand Glassed, High-Performance Surfboards

Hand glassed surfboards utilizing polyurethane cores, wood stringers, and premium epoxies represent a blend of traditional craftsmanship and modern technology, resulting in high-performance boards with exceptional durability and aesthetic appeal.

Polyurethane cores provide the foundational structure of the surfboard, offering a balance of lightweight construction and resilience to withstand the rigors of surfing. The use of wood stringers enhances the board’s strength and responsiveness, adding flex and torsional rigidity while maintaining a natural aesthetic.

Premium resins are employed in the lamination process to ensure superior bonding and water resistance, enhancing the longevity and performance of the surfboard. These resins provide a strong, lightweight coating that protects the board from delamination and maintains its structural integrity even in challenging conditions.

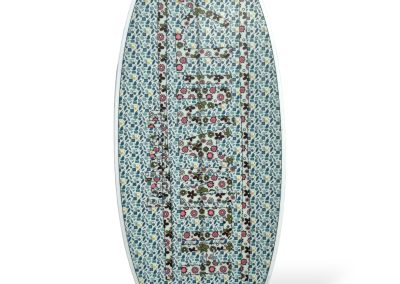

Moreover, one of the distinguishing features of these surfboards is the ability to digitally print super opaque, photorealistic images directly onto the board’s surface. This innovative printing technique allows for intricate designs, vibrant colors, and high-resolution graphics to be applied, transforming the surfboard into a personalized work of art. Whether it’s capturing breathtaking landscapes, showcasing artistic illustrations, or expressing individual creativity, this customization option adds a unique touch to each board, further enhancing its visual appeal and making it stand out in the water.